End-to-End Solutions

Your Fly Ash — Our Machinery

A Greener Tomorrow

We don't just sell machines — we provide smart, sustainable, and profitable solutions that help thermal power stations comply with regulations and thrive in a circular economy.

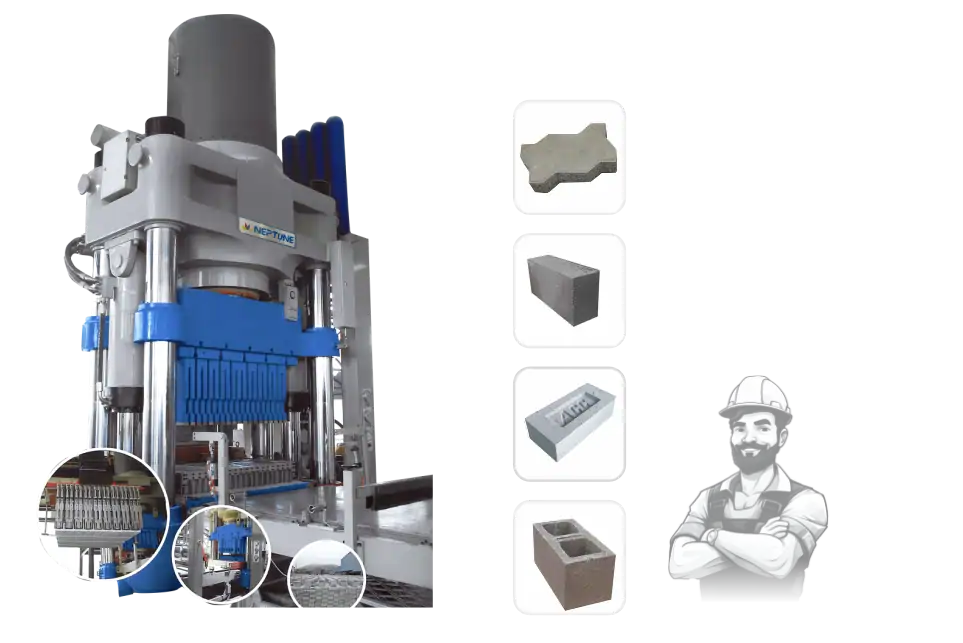

From Power Plant Ash to Powerful Bricks – Engineered by Neptune

Neptune Industries provides advanced machinery solutions for thermal power plants to convert fly ash waste into high-quality construction materials such as fly ash bricks, blocks, and pavers. With over 30+ years of engineering expertise and more than 1300 domestic installations, our company offers fully and semi-automatic machines with production capacities ranging from 10,000 up to 4,00,000 bricks per day.

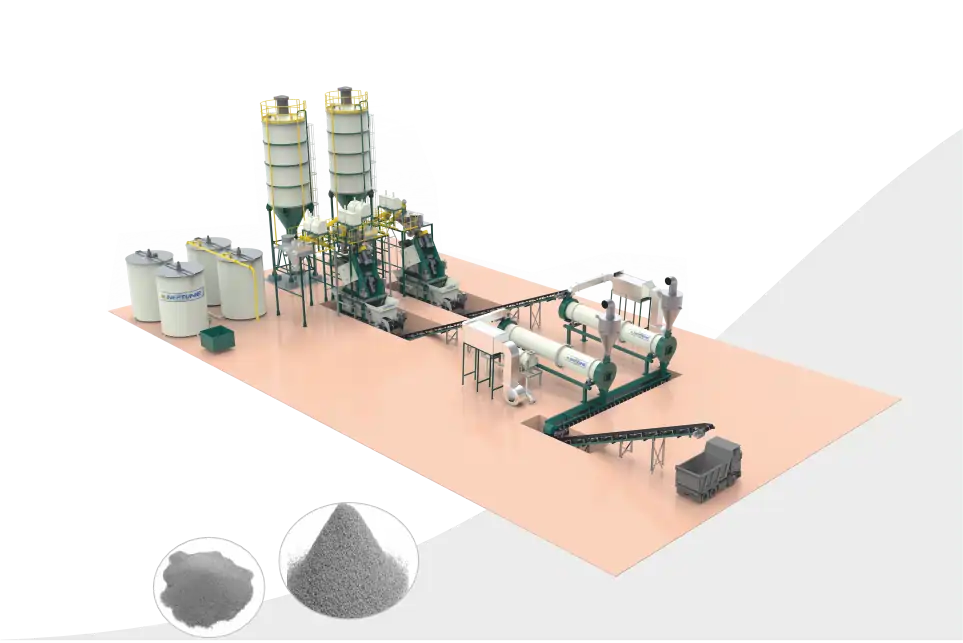

Fly Ash to Sand: Turning Waste into Construction Gold.

Ash To Sand: Neptune Industries offers a technologically advanced solution to convert dry fly ash into fine artificial sand, suitable for construction. capable of handling ash volumes from 5 TPH to 50 TPH, depending on plant size and application requirements.

Why Partner

with Neptune Industries?

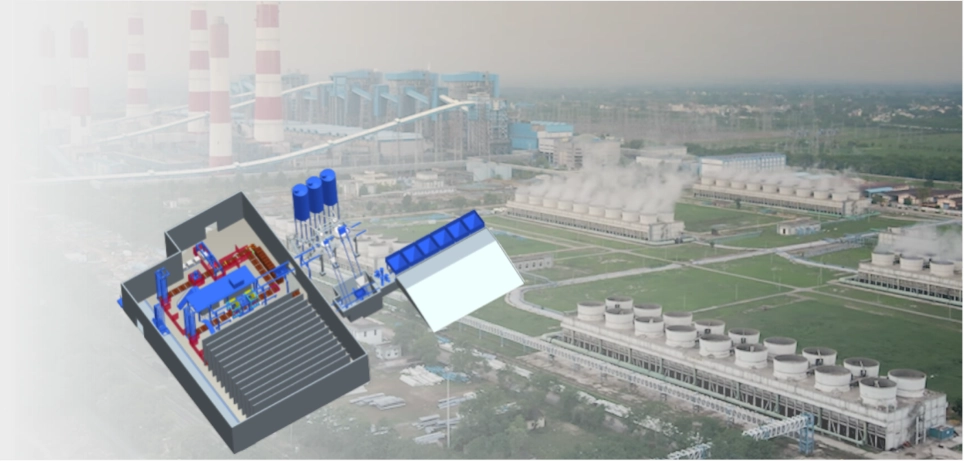

Case Study

Discover how our cutting-edge machine installation has not only enhanced operational efficiency but also earned the trust and satisfaction of our valued customers through proven results and exceptional performance

Revolutionizing fly ash utilization with India's largest plants at NTPC SIPAT-CG and NTPC Dadri-UP.

Neptune takes pride in successfully executing large-scale fly ash utilization projects at NTPC SIPAT-CG and NTPC Dadri-UP. These initiatives have enabled the production of 1,00,000 fly ash bricks per day at SIPAT and 2,00,000 bricks per day at Dadri, including concrete pavers and blocks.

-

Installed a Fully Automatic Brick Plant at JSPL with gratitude for the opportunity.

We commissioned a fully automated plant at Jindal Steel and Power Limited (JSPL) Raigarh, in partnership with FRIMA GmbH, with a production capacity of approximately 2,00,000 bricks per day.

-

Customer

Success Stories

Discover how our solutions drive real results and lasting success for our clients across industries..