Capable of producing up to 25,000 blocks per day. Our advanced, energy-efficient machines ensure high productivity and sustainability, making eco-friendly construction more accessible. Partner with us for reliable and innovative CSEB production solutions..

Next-Generation

Innovate. Build. Sustain.

We have developed top-quality, indigenously designed technology for Fly Ash Bricks, Cement Bricks, Concrete Blocks, Pavers, Dry Mix Mortar, CSEB, LDA/LWA, AAC, and other building material plants. Our solutions offer high performance, reliability, and sustainability, supporting the growth of the construction industry in India.

Machinery that manufactures Bricks, Blocks, and Pavers using UHDP Technology.

UHDP Technology: Our machinery, featuring 150 to 1600 Ton Hydraulic Presses, is designed to produce 10,000 to 4 Lakh Bricks per Day. Utilizing UHDP Technology, these machines offer high strength, precision, and durability. They also come with eco-friendly solutions, promoting sustainability in the construction industry.

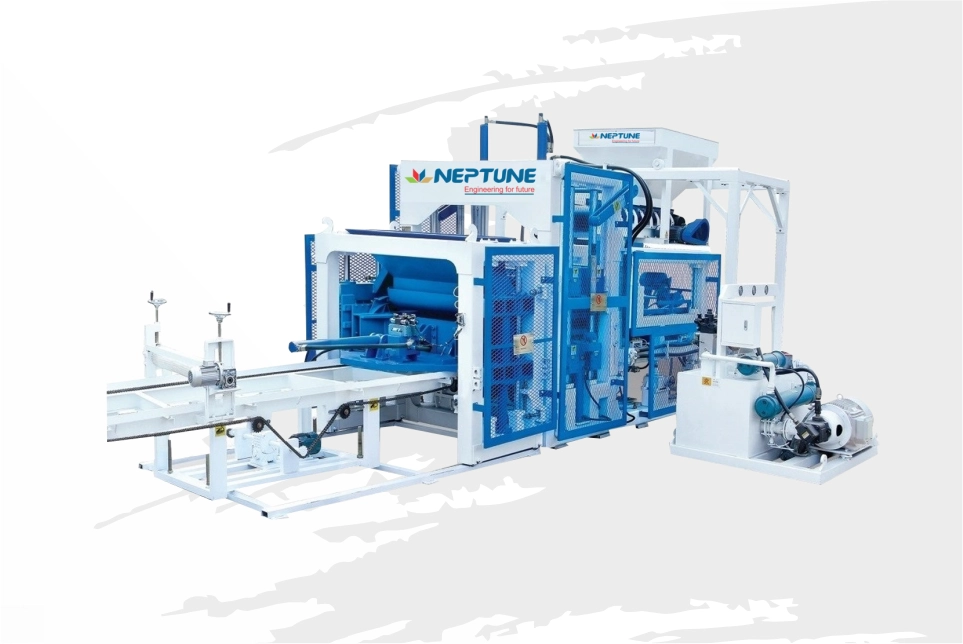

Machinery comes high-tech servo-type vibro-compacting technology for producing Bricks, Blocks, and Pavers.

Vibro-Compacting Technology : Our machinery features high-tech servo-type vibro-compacting technology for producing Bricks, Blocks, and Pavers. The plant production capacity ranges from 5,000 to 2 Lakh units per day, depending on the product type, such as bricks, blocks, pavers, etc. This advanced technology ensures optimal compaction, enhanced strength, and precision, delivering superior quality products for every construction need.

World-Class Dry Mix Mortar Plant: Homogeneous Blending for Superior Quality Mixes

Dry Mix Mortar Plant: A dry mortar plant includes silos for storing raw materials like aggregates, cement, and additives. These are dosed, mixed to the required composition, and then made available for bagging, silo storage, or direct loading into trucks. Neptune offers plants with capacities from 5 TPH to 30 TPH, including 10 TPH, 15 TPH, 20 TPH, and 25 TPH models..

Our Expanding

Market Segment

Unlock new opportunities in the expanding market segment with Building Material products, offering flexible and industry-specific solutions.

Case Study

Discover how our cutting-edge machine installation has not only enhanced operational efficiency but also earned the trust and satisfaction of our valued customers through proven results and exceptional performance

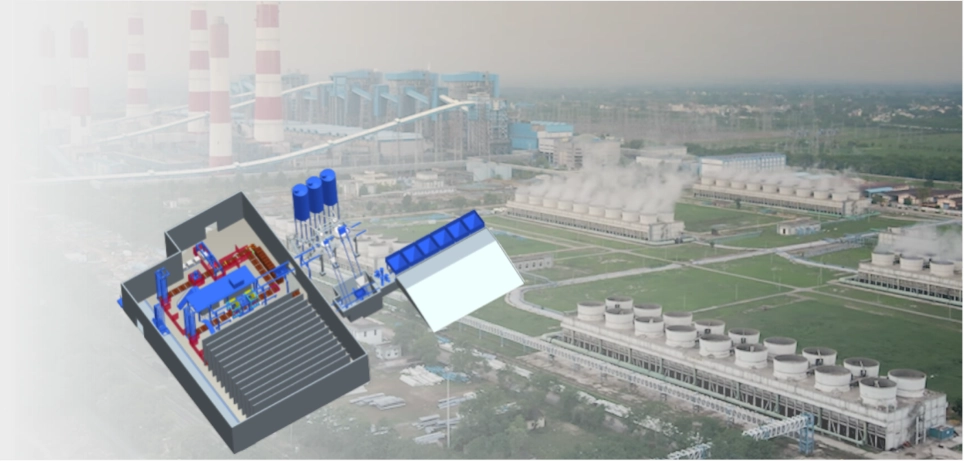

Revolutionizing fly ash utilization with India's largest plants at NTPC SIPAT-CG and NTPC Dadri-UP.

Neptune takes pride in successfully executing large-scale fly ash utilization projects at NTPC SIPAT-CG and NTPC Dadri-UP. These initiatives have enabled the production of 1,00,000 fly ash bricks per day at SIPAT and 2,00,000 bricks per day at Dadri, including concrete pavers and blocks.

-

Installed a Fully Automatic Brick Plant at JSPL with gratitude for the opportunity.

We commissioned a fully automated plant at Jindal Steel and Power Limited (JSPL) Raigarh, in partnership with FRIMA GmbH, with a production capacity of approximately 2,00,000 bricks per day.

-

Customer

Success Stories

Discover how our solutions drive real results and lasting success for our clients across industries..

UPCOMING EVENTS

Join us at our upcoming events! Discover our innovative technologies and connect with our experts to learn more about what we have to offer.

World ConEx-2025

February 14–16, 2025,

Shriram Business Park, Vidhan Sabha Road, Raipur, Chhattisgarh

Earthcon Expo-2025

February 21-23, 2025

HITEX Exhibition Center,

Hyderabad