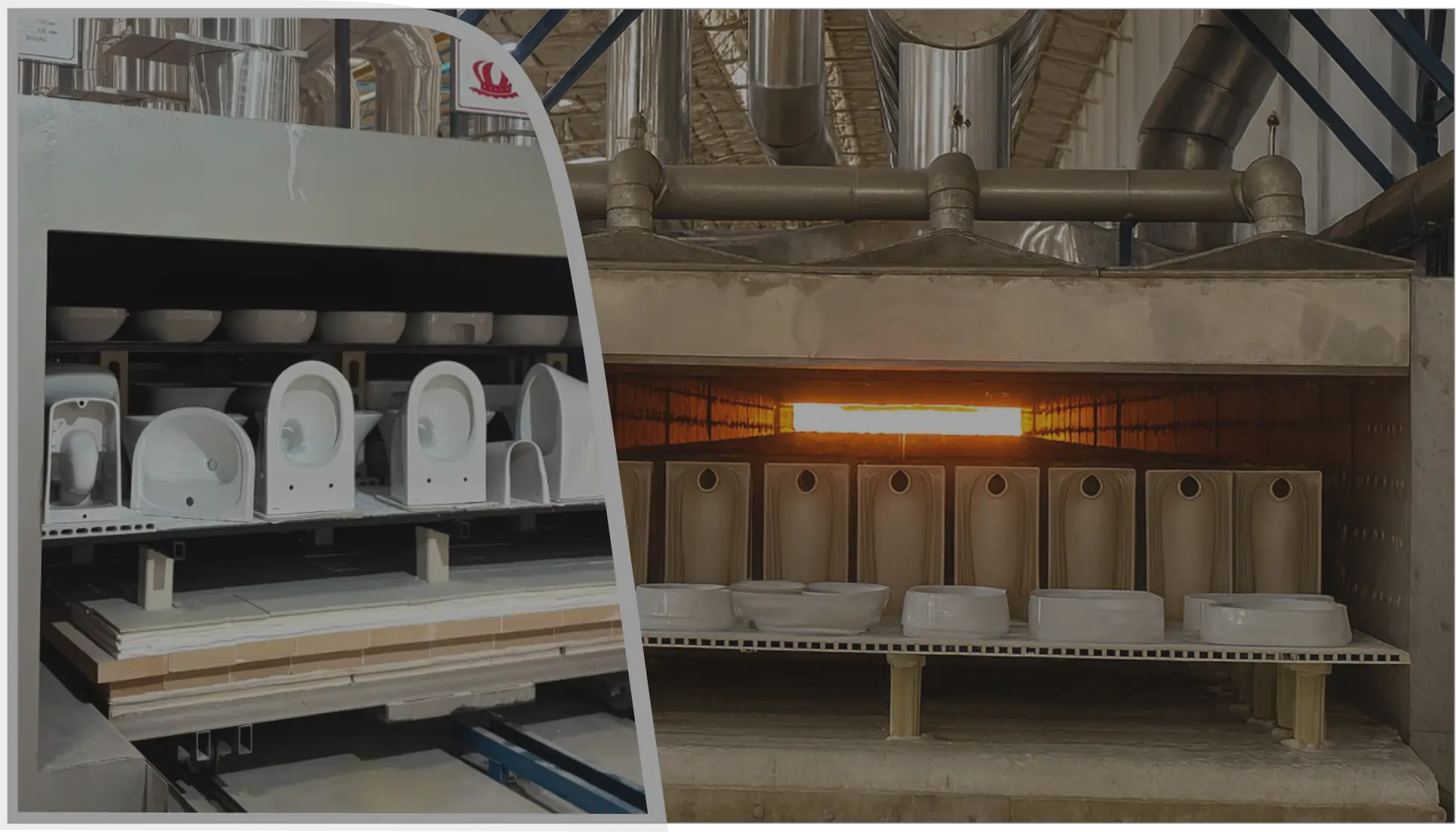

Firing and re-firing plants for ceramics and porcelain insulator manufacturing

Neptune Industries supplies modular tunnel & shuttle kilns, kiln cars, hydraulic push–pull systems and integrated glazing/sintering solutions for sanitary ware, industrial ceramics and porcelain insulators.We deliver standalone equipment or full turnkey plants with waste-heat systems, process engineering, commissioning and after-sales support.

Joint Venture for Sanitary-ware Kilns

Neptune Industries and HLT|DLT form an official joint venture to supply tunnel & shuttle kilns, turnkey firing plants and after-sales support for sanitary ware, ceramics and porcelain insulators in India and select overseas markets.

Tunnel Kiln — Continuous High-Throughput Firing

- Continuous firing: products move on cars or conveyors through preheat → firing → cooling zones.

- Uniform temperature control across zoned sections ensures consistent product quality.

- High throughput and low per-piece energy cost with integrated waste-heat recovery (WHR).

- Ideal for mass production: sanitary ware, tiles, tableware, and high-volume porcelain insulators.

Shuttle Kiln — Flexible Batch Firing for Ceramics & Insulators

- Batch operation: products are loaded on kiln cars and shuttled into discrete chambers.

- Each chamber runs independent ramp–soak profiles for precise control and re-firing.

- High flexibility for mixed SKUs, R&D, and high-temperature technical ceramics.

- Best for small-to-medium production runs: sanitary ware, tableware, technical ceramics, and HT/LT insulators.