Engineered for strength, efficiency & sustainability

Building the Future with Smart Cement Machinery!

Our advanced machinery allows you to manufacture a wide variety of cement-based construction products tailored for modern infrastructure.

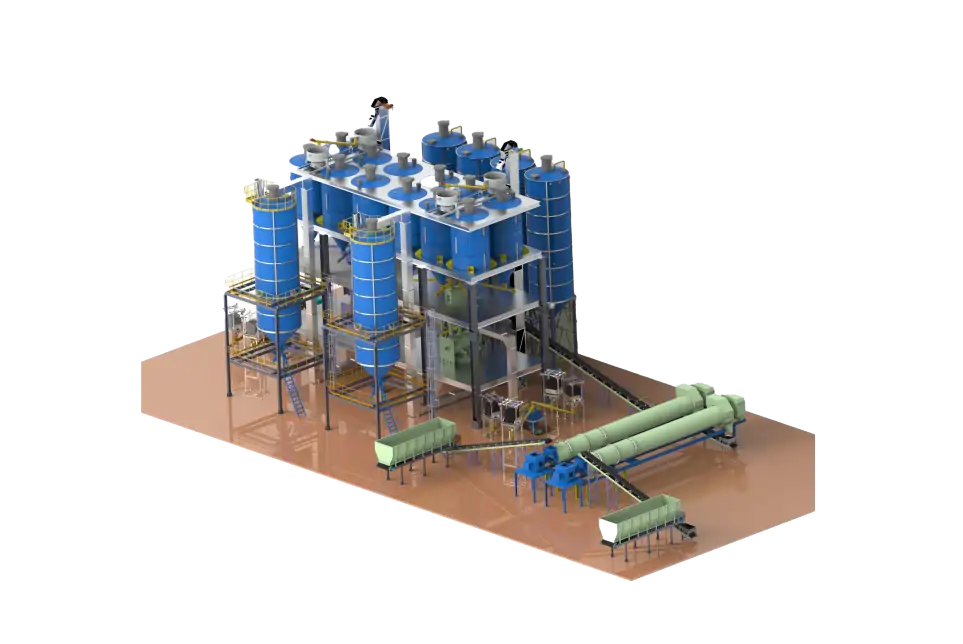

Dry Mix Mortar Plant – Versatile Solutions for the Cement Industry.

Our advanced Dry Mix Mortar Plant is designed to serve the cement industry's growing demand for high-performance, pre-mixed solutions. Engineered with cutting-edge dry mix technology, this plant supports universal applications—offering a single, integrated solution for a wide range of construction needs. With a production capacity ranging from 5 TPH to 50 TPH, our plant ensures efficiency, consistency, and quality across various mortar types..

Mix smarter, faster, and better – with our next-generation intensive mixer.

The Counter Current Intensive Mixer: is one of the most advanced and effective mixing technologies available today, specifically designed for rapid, homogeneous, and repeatable mixing performance. Ideal for the cement industry, this mixer delivers unmatched consistency across a wide range of formulations. At the core of its design is a rotating mixing pan that continuously moves material toward strategically placed mixing plows and a side wall scraper. This ensures thorough blending of all components with minimal mixing time—resulting in fast and uniform output.

Engineered Drying Solutions for the Cement Industry.

Rotary Dryer Technology : Our drying systems are engineered to efficiently reduce the moisture content of raw materials used in cement-based applications. The process uses a rotating drum or chamber where wet materials are exposed to high-temperature air generated by multi-fuel burners. The system can operate using coal, gas, diesel, biomass, or alternative fuels, depending on availability and customer preference.

Core

Functionalities & Benefits

Moisture Control

Dryers ensure raw materials like sand, fly ash, and additives are dried to the right moisture level—critical for consistent cement product quality.

Higher Efficiency, Lower Costs

Automated mixing and drying systems save time and energy, reducing fuel and labor costs.

Consistent, Repeatable Batches

With counter-current mixers and precise control systems, every batch is uniform—minimizing waste and rework.

Wide Range of Applications

One plant can produce various dry mix products: wall plaster, screed, adhesive, waterproofing, and more—ideal for construction materials manufacturing.

Ready for Packaging or Delivery

Once mixed and dried, materials are ready for bagging, storage, or loading into trucks for delivery—streamlining your production line.

Customer

Success Stories

Discover how our solutions drive real results and lasting success for our clients across industries..